Waveform library

The library contains information about vehicles sensors, actuators, ignition systems and complex engine diagnostics. You may find here the examples from both good and bad vehicles, videos, and files. If you want to open the waveform file, you need to download the USB Oscilloscope program.

Vehicle diagnostics

Most all scanners read error codes about the same. However, reading Diagnostic Trouble Codes (DTCs) is not diagnostics, it is only reading the control unit's interpretation of data along with a short description of the code meaning.

A technician has to decide if the “diagnosis” offered by the control unit is correct, and whether additional testing and measurements are needed. The preferred method of diagnosis for cost and time reasons is to determine the cause of the failure with little or no disassembly of the diagnosed system. Since there is always a chance of incorrect diagnosis, best practice is to use an alternative method to confirm the failure without relying on the control unit's interpretation.

Some alternative methods are to read and interpret sensor values as reported by the scan tool, using bidirectional control to activate control unit outputs such as relays, solenoids, and motors, or by using specialized monitoring software. The problem here is that we are again relying on the control unit's interpretation of sensor data, even if in a raw format. In some cases if would be preferable to utilize techniques that do not rely on the control unit's and or the scanner's interpretation of the data.

Oscilloscope diagnostics and waveform analysis

Most all vehicle engines operate on similar principles and are arranged about the same.

Mechanically we have the crankshaft, connecting rods, pistons, valves and so on. Electrically we have roughly the same set of sensors and actuators, fuel supply system, and ignition systems. Since this is the case, certain diagnostic principles and techniques are applicable to most all engines, regardless of the brand and model of the vehicle.

Some alternative methods are to read and interpret sensor values as reported by the scan tool, using bidirectional control to activate control unit outputs such as relays, solenoids, and motors, or by using specialized monitoring software. The problem here is that we are again relying on the control unit's interpretation of sensor data, even if in a raw format. In some cases if would be preferable to utilize techniques that do not rely on the control unit's and or the scanner's interpretation of the data.

In the case of the USB Autoscope, the necessary algorithms for various waveform analysis processes are contained in files called scripts. A number of different scripts exist for analysis of various vehicle faults.

CSS script

The CSS script allows us to identify which cylinders are misfiring or have decreased power contribution as well as the reason for the problem. The script does not rely on the capabilities of the scanner or the on board diagnostic system and is able to provide more information to analyze the cause of the problem. The script works by analysing the power contribution from each cylinder during engine operation in different modes. The data is displayed in the software under a tab labeled "Efficiency", where the gray trace shows changes of engine speed during the measurement period. Different color graphs show the contribution from each of the cylinders.

Px script

The Px script uses a pressure transducer installed in place of a cylinder’s spark plug. The script allows for checking the characteristics of the cylinder, intake system, exhaust system and the timing system in order to evaluate the relative impact of these systems on the engine and each other.

This particular software automatically analyzes the cylinder pressure waveform and generates a print out or report with a number of additional parameters and characteristics of the engine and the associated control unit. The calculated values are pneumatic and geometric characteristics of the cylinder; the list of found deviations is displayed in the form of text messages. To improve speed and accuracy of valve timing research, the cylinder pressure waveform is converted into a diagram of the gas amount in the cylinder and is displayed in two different ways, using a script.

ElPower script

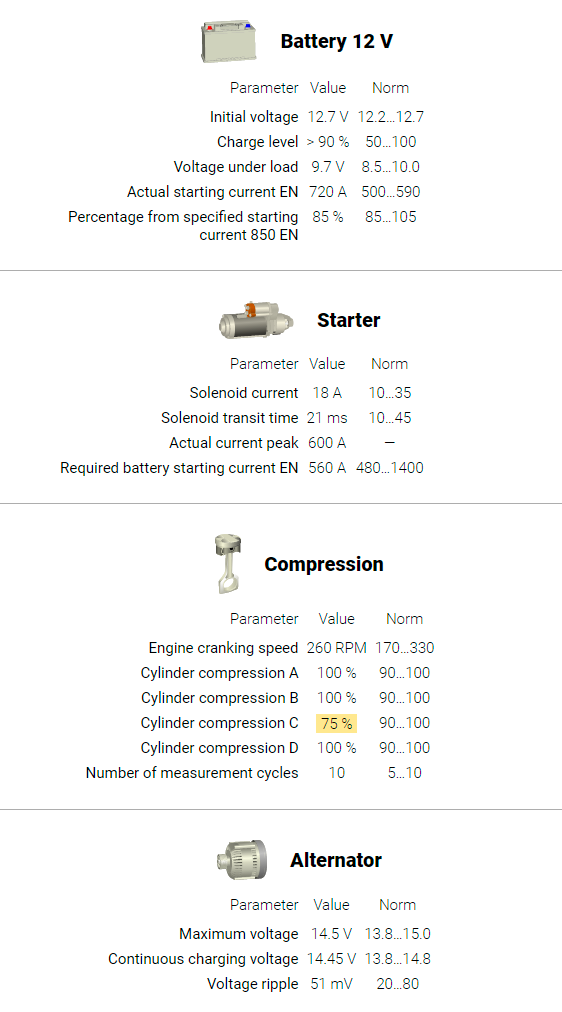

The ElPower script is designed to diagnose the vehicle starting and charging system, as well as to measure the relative compression of the cylinders of gasoline and diesel engines. It allows you to check the characteristics and condition of these vehicle components and systems:

- battery

- glow plugs of a diesel engines

- starters

- relative compression in the engine cylinders (can be measured without the use of a current clamp)

- alternator

In the process of analyzing the voltage waveform at the battery terminals and the current waveform obtained through the use of a current clamp, the ElPower script generates multiple report tabs, where it displays a number of the measured and calculated characteristics of the system components. It also provides an assessment of the consistency of the battery characteristics with the characteristics of the starter. If it detects any deviations or malfunctions, the script automatically displays appropriate messages.