Diesel diagnostics

| Pressure sensing Beru glow plugs |

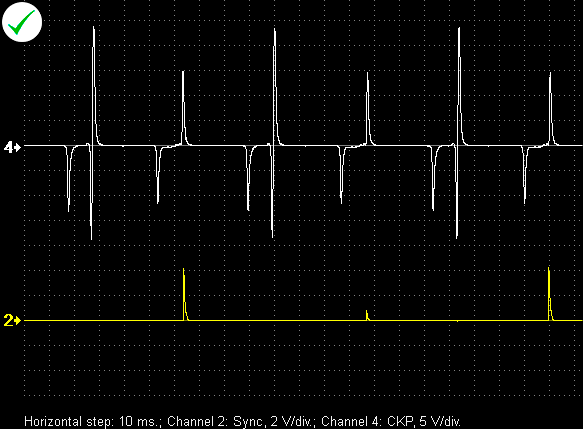

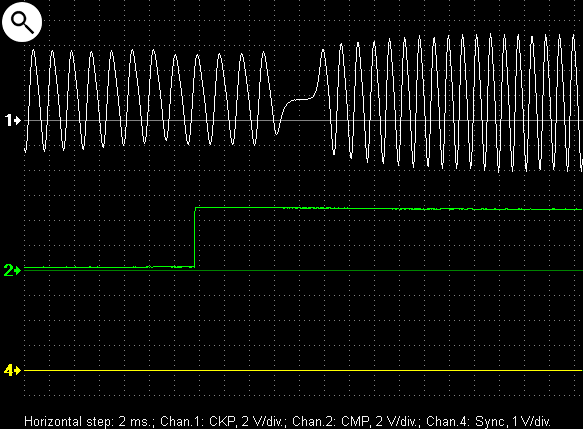

| Cam Crank Correlation on a Nissan YD22ETI |

Electronic Engine Control Sensors

Actuators

| Idle Air Control Valve |

| Evaporative Emission Control System Purge Valve |

| Exhaust Gas Recirculation Valve |

| Fuel Injector |

| Continuous Variable Valve Timing |

| Fuel Pump |

Ignition Systems

| Distributor Ignition |

| Distributorless Ignition System |

| Coil-On-Plug Ignition System |

Complex Engine Diagnostics

| CSS script |

| Px script |

| ElPower script |

| CKP-CMP synchronization |

Software

| How to install Flash Player |

| How to generate formula |

| Software updates |

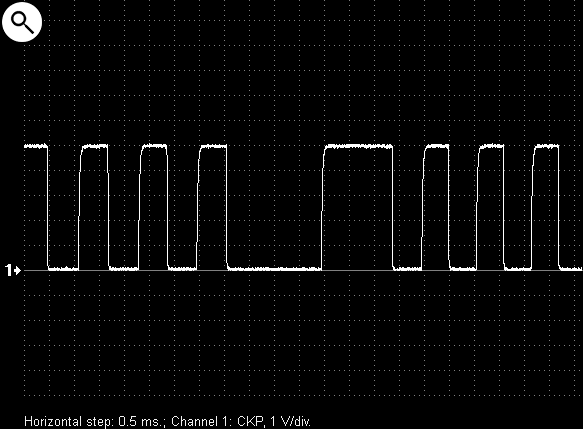

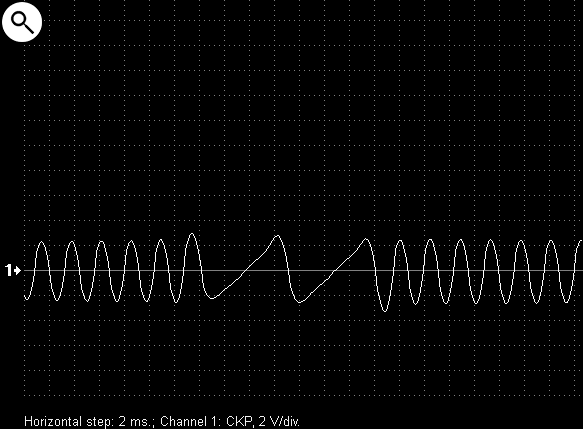

Crankshaft Position Sensor

The crankshaft position sensor is used to indicate the position and speed of the crankshaft. This information is used by the Power train Control Module (PCM) for ignition timing and fuel delivery.

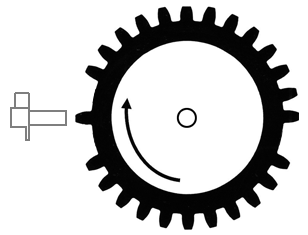

The sensor is located close to a disc or wheel containing a number of teeth or slots and affixed to, or cast as part of, the crankshaft. The distance between the sensor and the disc or wheel (often called a reluctor) is 0,8…1,0 mm, but verify specification with the manufacturer because this distance is critical to the proper operation of the sensor. The number of teeth can vary and depends on the number of cylinders and how accurate the system needs to be. One example uses 35 teeth for a 360 degree disc.

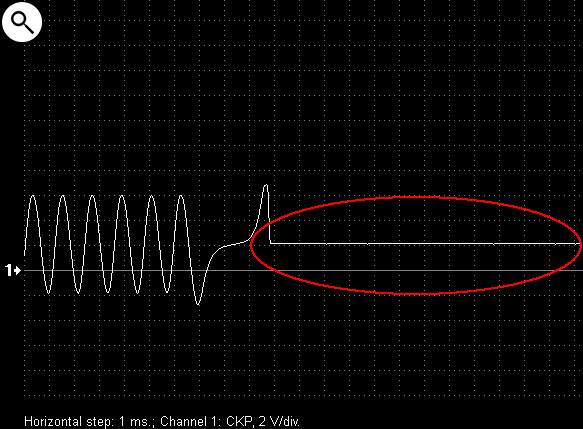

One tooth is often missing and is used to indicate piston position. The missing tooth often correlates to Top Dead Center (TDC) of cylinder number 1 (or the timing cylinder, if different).

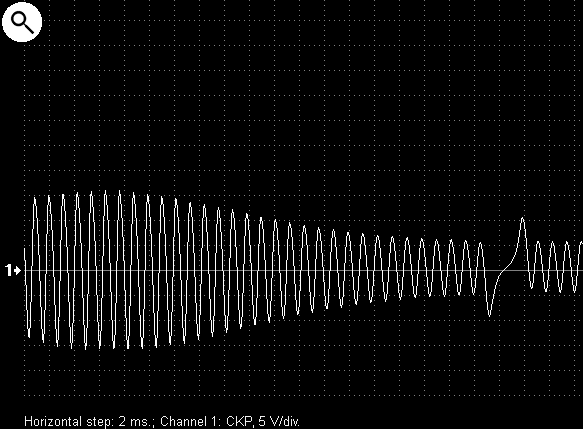

The amplitude or voltage of the signal depends greatly on engine RPM and distance between the sensor and the reluctor. Specifications may vary, but the voltage should generally be more than plus or minus 6 V at idle and at least plus or minus 0,5 V while cranking the engine. The frequency of the signal will increase with engine RPM as well.